A few weeks ago I was on vacation in remote Eastern Utah - in Canyonlands National Park, to be precise and because we had some "down time" in the evenings, after hiking, after sunset, I was able to set up a portable HF station. Using the homebrew end-fed halfwave antenna (EFHW) of Mike, K7DOU - one end of the rope tied around a rock laying on a shelf of slick rock some 40 feet above ground level and the other end tied to a bamboo pole attached to my Jeep - I connected my FT-100 through a manual tuner as the VSWR of the EFHW wasn't necessarily very low on some of the higher bands.

|

| Figure 1: 150 Watt Samlex sine wave inverter, sitting on the workbench. Click on the image for a larger version. |

For whatever reason, I had brought along my old lap top and sound-card interface so I could work some digital modes, specifically FT-8 - a mode that I was familiar with, but had personally never worked. The battery in my laptop had discharged, so I needed an alternate source of power and I connected my 150 watt Samlex Sine Wave inverter (a PST-15S-12A) to the battery to power the computer's power supply.

The (expected!) result of this was a tremendous "hash" all across the HF spectrum - an obvious result of the various high-power converters contained within the inverter. On some bands the interference wasn't too bad, but on others the result was unusable. While the battery charged, I operated on the band (20 meters, IIRC) that wasn't as badly affected.

I left the inverter running and the laptop battery charging during the cooking and eating of dinner, and with a reasonable amount of power banked I could turn off the inverter and get a zero noise floor while operating.

Why so noisy?

Modern AC inverters first convert the DC input power to something around the peak voltage found on the AC output - typically around 155 volts for 120 volt mains. This conversion is done using a switch-mode inverter with a transformer, typically operating in the 20-60 kHz range and this output is rather rich in harmonics.

For the less-expensive "modified sine wave" inverters, the DC output is chopped, typically using an "H" bridge switch using FETs (Field Effect Transistors) with the duty cycle being varied to provide the equivalent of a 120 volt sine wave - and this switching can also add a bit of extra RFI, most notably in the form of a "buzz" - but this action produces less energy at radio frequencies than the initial voltage conversion.

The "Sine Wave" inverters perform the same step of producing the high DC voltage, but will chop the output into much smaller bits. The method that this is done can vary, but it's sometimes done by using a "buck" type switching converter to transform the higher voltage into a varying - usually lower - voltage to simulate a sine wave on the output. This second conversion adds yet another source of RF interference atop what is likely already the significant source that already present in the high voltage converter.

Comment: The power converter (wall wart) that I was using to charge my laptop is particularly quiet, so I did verify that the vast majority of noise was, in fact, from the AC inverter.

Quieting the inverter:

Fortunately, the internal space of this inverter wasn't terribly cramped so there was just enough room to add the necessary components to suppress the RF "hash" that was being conveyed on both the DC and AC lines. While the methods of doing this sort of RF quieting have been discussed in previous blog posts (see the references at the end of this article) I'll review them in detail here.

Snap-on chokes won't do!

It's worth noting (several times!) that simply winding the power cord (DC and/or AC) around a ferrite device (e.g. a clamp-on or even a large toroid) would likely NOT be enough to solve this problem. While doing so may knock down RFI by, perhaps, 6-10 dB - maybe 20 dB if one is really lucky - this sort of noise egress must often be attenuated by several 10s of dB to effectively quash it. In other words, knocking down the "grunge" by 1-2 S-units is nice enough, but there will still be a lot of hash left over to bury the weakest signals!

Internally, this inverter did pass through some rather large ferrite cylinders the DC input and (separately) AC output connections, but this very small amount of inductance would have practically no effect at all at HF - likely having been added to make a dent in the noise at VHF so that it would pass muster when subjected to EMC compliance tests.

Filtering the AC output:

I presumed (but didn't actually measure) that the majority of the noise being radiated would be from the AC output as it is "closest" to the circuits most likely to generate a lot of noise, so I concentrated most of my effort there.

The most helpful component in filtering the mains voltage output is the bifilar choke - several varieties of these being displayed in Figure 2. This component consists of two windings in parallel on the same ferrite core - typically both leads of the mains voltage. For the low-frequency AC currents, the halves of the choke carry equal and opposite current so there is no DC component to magnetize the core and reduce its efficacy due to saturation, but because RF energy is likely not flowing in a differential manner as is the AC mains voltage, the inductance of the two parallel windings come into effect - the magnitude of this typically being in the 10s of microHenries to milliHenries range.

Where does one get these things? They can be found at surplus outlets if you look around, but perhaps the easiest source is from defunct PC power supplies: These devices, found in supplies made by reputable manufacturers, are typically the first things through which the AC mains voltage pass (after any fusing) before going to the rest of the circuitry.

This much inductance has significant impedance to RF energy - but inductance alone will have only limited efficacy and intrinsic capacitance of the windings will also reduce the amount of attenuation that would otherwise happen - as would have winding the mains cord/cable on a ferrite toroidal core as noted previously - so capacitors are also required to be placed strategically to help shunt away some of the residue.

The diagram in Figure 3 shows the as-installed filter. As can be seen, two separate bifilar filters (both of them being the sort as seen as the second from the lower-right in Figure 2) were used to maximize attenuation. In this circuit, C3 and C4 are used to force any RF on the two wires to be common-mode to maximize the efficacy of the bifilar chokes' attenuation and any residual RF - which will be at rather low level and high impedance - will then be shunted to the metal case of the inverter by capacitors C1 and C2.

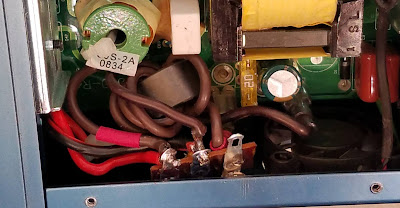

Figure 4 shows the installation of the filtering components in the inverter. C1 and C2 are the disk-shaped blue capacitors seen in the upper-left, mounted directly to the inverter's single AC outlet and capacitor C3 is just in "front" of the two round disks, also mounted directly to the socket. The first inductor, L1, can be seen in the shadows, connected to the outlet with very short, flexible leads to the plug.

Earlier, I had removed this outlet from the body of the inverter and mounted C1, C2, C3 and L1 to it and with a bit of "tetris" action, was able to reinstall the outlet back in place with the components attached. From that point I installed C4 (to the "other" side of L1) and the (orange) connecting wires from C4 to L2, which is shown floating in space.

You might ask why there isn't another capacitor (like C4) across the "inverter" side of L2 - or other capacitors to ground other than C1/C2: There is already a degree of filtering on the AC output of the inverter, so there is little point in adding another capacitor like C4. As for other capacitors to "ground" like C1/C2 elsewhere in the circuitry: These were deemed unnecessary - and doing so, particularly at the "inverter" side of L4 would simply put relatively strong RF currents onto the ground lead (e.g. inverter's case) - and our cause won't be helped in making RF currents appear where don't need them to be.

Filtering the DC input:

While I would presume that most of the noise would be emitted via the AC output port, filtering the DC port must be considered as well. With the inverter's rating being 150 watts, the maximum current on the AC output would be around 1.25 amps and rather light-gauge wire could be used in the inductors - but because this same power level represents 12.5 amps at 12 volts (likely more if the battery voltage is on the low side) the filtering inductance must be made using much larger wire.

Rummaging around in my box of toroids, I found a ferrite device that was about 1" (2.54cm) in outside diameter and wound as many turns of 14 AWG flexible wire onto it as would fit (about 6 bifilar turns) and measured it to have about 30 uH of inductance per winding. This may not seem like much, but at 1 MHz, this represents about 180 ohms of reactance.

In referring to Figure 5, above, you'll notice that it is pretty much identical to that of the output filter - except that there is only one section of filtering. The capacitor values are different, too: C1 and C2 are 0.1uF units that shunt residual RF getting through L1 to ground (the case) while C3 is a low-ESR electrolytic connected across the DC leads to help force any residual AC noise on the DC lead to common-mode. Compared to the 180 ohms of reactance of the DC bifilar choke (at 1 MHz) a good-quality, monolithic ceramic capacitor like the 0.1uF units are likely to have well under an ohm of impedance and very little of the RF hash will remain after they do their job to bypass it to the chassis ground.

Because of the limited amount of room, only one inductor was used - although it would likely be possible to have crammed another in the limited space should the above filter have proved to be inadequate (it wasn't).

As can be seen in Figure 6, a small terminal strip is visible and to it is mounted C1-C3 (not visible as they are obscured by the strip itself). The mounting point for this strip is the ground lug near the DC input cable and the center lug is the common point for C1 and C2.

An important point to mention is the fact that this inverter - like many - have their DC and AC lines isolated from the case - and that's also important here: Because the DC has no connection to the inverter's metal case, ALL of the DC current passes through L1 of Figure 5 - but with both halves carrying the same current, the core is not magnetized: Magnetizing the core would likely cause it to saturate and the result would be its effective inductance plummeting - possibly reducing its efficacy as an RF filter. It is for this reason that a bifilar choke was used on the DC input as well.

As with the AC output, the "inverter" side of L1 of Figure 5 also lacks a common-mode capacitor, but this is well represented on the input of the inverter itself with its own, built-in capacitor.

Additional comments:

Figure 7 shows the final arrangement of the added components. In the upper-left corner can be seen the components of the DC input filter with come clear RTV (silicone adhesive) added to the top of the terminal strip to insulate it and keep any metal parts of it from touching the bottom cover when it was reinstalled.

On the right side is the AC output filter and on the foreground can be seen L2, now with the "hot" terminals covered by heat-shrink tubing. This choke was first attached "temporarily" to the inverter's end plate using instant (cyanoacrylate) glue - and then several large blobs of RTV were later added to permanently hold it in place. Just above it can be seen the orange wires that connect L2 to L1 and these components were also stabilized with rather large blobs of RTV to keep them from "flapping in the breeze". It's worth noticing that the original ferrite cylinder is still on the AC output connection (on the black and white wires) where it connects to L4 - mainly because there was still room for it, and its efficacy, such as it is, is likely only enhanced by the addition of the new filtering components.

Did it work?

You might ask the question: Did this filtering work?

The answer is yes. Placing a portable shortwave radio next to either the DC or AC power leads from the inverter, one can't detect that it is running at all. If the radio is placed right atop the inverter, some hash can be detected, but this is likely from direct radiation of magnetic fields from the inductors/transformers within, but detectable amounts do not appear to be emanating from DC and AC wires themselves - and that's the important part as they would otherwise be acting as antennas.

Perhaps the most important part of this modification is the fact that any bypass capacitors are placed on the "quiet" (not the inverter) side of the filtering inductances and that these bypass capacitors are connected, with short leads, to a large, common-point ground - namely the case of the inverter. If any of the "ground" leads had been more than an inch or two long, it's likely that the impedance of it would have reduced the efficacy of the filtering - but the case, being a solid chunk of extruded aluminum, forms a nice, low-impedance tie point - effectively a single-point ground, preventing an RF current differential between the DC input and AC output leads.

* * *

Follow-up:

I've used this (modified) inverter several times, running strings of LED (Christmas) lights to illuminate the area around the camp site - often within a few feet (a meter or so) of the HF antenna and attached to the lower portion of the antenna mast and there was NO noise audible whatsoever from the inverter in the form of birdies from switching harmonics.

What was slightly audible was "space modulation" caused by the diode action of the LEDs themselves at the 60/120Hz AC frequency causing a small amount of amplitude modulation on received signals. Interestingly, there was no audible noise generated by the LEDs themselves across the HF spectrum.

* * *

Links to other articles about power supply noise reduction found at ka7oei.blogspot.com:

- A high-current DC noise filter for UPS or RV use. What if you have an inverter or UPS that is large - as in the multi-kilowatt class? This article describes quieting one such device.

- Containing RF noise from a "pure" sine wave UPS. Even when it is not operating your sine wave UPS may be producing a lot of HF radio interference!

- Completely containing switching power supply RFI - link. Sometimes

it can be difficult to quiet a switching power supply, so it may be

necessary to put it in a box with strong filtering on all of the

conductors that enter/leave.

- Minimizing VHF (and HF) RFI from electronic ballasts and fluorescent tubes - link.

Electronic light ballasts, like many switching power supplies, operate

in the LF frequency range so "cleaning them up" at VLF/LF/MF frequencies

can be a challenge.

- Quieting high current switching power supplies used in the shack - link. This

page describes techniques that can be used to reduce the amount of RF

energy produced by switching power supplies that you may be using to

power your radios. Again, higher-inductance chokes may be required at

VLF/LF/MF frequencies.

- Reducing switching supply racket - link. This describes techniques that can be used to beef up the filtering for switching supplies in general.

This page stolen from ka7oei.blogspot.com

[End]

No comments:

Post a Comment

PLEASE NOTE:

Be sure to be logged in to your Google account to post.

While I DO appreciate comments, those comments that are just vehicles to other web sites without substantial content in their own right WILL NOT be posted!

If you include a link in your comment that simply points to advertisements or a commercial web page, it WILL be rejected as SPAM!