Note: As of 9 February, 2022, this signal is still there, doing what it was doing when this post was originally written.

* * *

Listening on 20 meters, as I sometimes to, I occasionally noticed a loud "click" that seemed to pervade the upper portion of the band. Initially dismissing it as static or some sort of nearby electrical discharge, my attention was brought to it again when I also noticed it while listening on the Northern Utah WebSDR - and then, other WebSDRs and KiwiSDRs across the Western U.S. Setting a wide waterfall, I determined that the source of this occasional noise was not too far above the 20 meter band, occasionally being wide/strong enough to be heard near the top of the 20 meter band itself.

|

| Figure 1: The carrier in question - with a few "clicks". In this case, the signal in question was at 14.390 MHz. Click on the image for a larger version. |

From central Utah, a remote station with a beam indicates that the bearing at which this carrier peaks is somewhere around northeast to east-northeast, but it's hard to tell for certain because of the normal QSB (fading) and the fact that the antenna's beamwidth is, as are almost all HF beams, 10s of degrees wide. Attempts were made to use the KiwiSDR "ARDF" system, but because it is effectively unmodulated, the results were inconclusive.

What is it?

The frequency of this signal appears to vary, but it has been spotted on 14.378 and 14.390 kHz (other frequencies noted - see the end of this article) - although your mileage may vary. If you listen to this signal sounds perfectly stable at any given instant - with the occasional loud "click" that results in what looks like a "splat" of noise across the waterfall display (see Figure 1), with it at the epicenter

Comment: If you go looking for this signal, remember that it will be mostly unmodulated - and that it will be subject to the vagaries of HF propagation.

When a weird signal appears in/near the amateur bands - particularly 20 meters - the first inclination is to presume that it is an "HFT" transmitter - that is, "High Frequency Trading", a name that refers not to the fact that they are on the HF bands, but that it's a signal that conveys market trades over a medium (the ionosphere) that has less latency/delay than conventional data circuits, taking advantage of this fact to eke margins out of certain types of financial transactions. Typically, the signals conveying this information appear to be rather conventional digital signals with obvious modulation - but this particular signal does not fit that profile. Why blame HFT? Such signals have, in the past, encroached in the 20 meter band and distrupted communications - see the previous blog post "Intruder at the top of the 20 meter amateur band?" - link.

Why might someone transmit a (mostly) unmodulated carrier? The first thing that comes to mind would be to monitor propagation: The amplitude and phase of a test carrier could tell something about the path being taken, but an unmodulated signal isn't terribly useful in determining the actual path length as there is nothing about it that would allow correlation between when it was transmitted, and when it was received.

Except, that this signal isn't unmodulated: It has those very wideband "clicks" could help toward providing a reference to make such a measurement.

What else could it be? A few random thoughts:

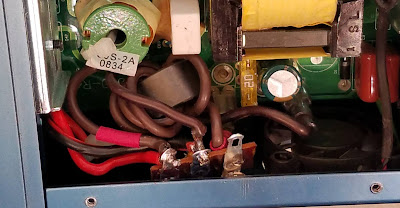

- Something being tested. It could be a facility testing some sort of HF link - but if so, why the frequency change from day to day? The "clicks"? Perhaps some sort of transmitter/antenna malfunction (e.g. arcing)?

- Trigger for high-frequency trading (HFT). Many high-frequency trading type signals are fairly wide (10 kHz or so) - possibly being some sort of OFDM - but any sort of coding imposes serialization delays which can negate some of the minimization of propagation delay being attained via the use of HF as compared to other means of conveying data over long distances. Likely far-fetched, but perhaps the "clicks" represent some sort of trigger for a transaction, perhaps arranged beforehand by more "conventional" means. After all, what possible means of conveying a trigger that "something should happen" exists than a wide-bandwidth "click" over HF? Again, unlikely - but seemingly so did something like HFT in the first place! Additionally, it would seem that the "other" HFT signals that had been present have mostly disappeared - to be replaced by, what? I suspect that they haven't just gone away!

A bit of analysis:

A bit of audio of this carrier, complete with "clicks" was recorded via a KiwiSDR. To do this, the AGC and audio compression were disabled, the receiver set to "I/Q" mode and tuned 1 kHz below the carrier and the bandwidth set to maximum (+/- 6 kHz) and the gain manually set to be 25 dB or so below where the AGC would have been. Doing this assures that we capture a reference level from the signal itself (the 1 kHz tone from the carrier) at a low enough level to allow for a very much stronger burst of energy (the "click") to be detected without worrying too much about clipping of the receive signal path.

The result of this is the audio file (12 kHz stereo .WAV) that you may download from HERE.

Importing this file into Audacity, we can zoom in on the waveform and at time index 13.340, we can see this:

Near the baseline (amplitude zero) we see the 1 kHz tone at a level of approximately 0.03 (full-scale being normalized to 1.0) but we can see the "clicks" represented by large single-sample incidents, one of which is at about 0.83. Ignoring the fact that the true amplitude and rise-time of this "click" is likely to be higher than indicated owing to band-pass filtering and the limited sample rate, we see that the ratio between the peak of the "click" and the sine wave is a factor of 27.7:1 or, converted to a power relationship, almost 29dB higher than the CW carrier.

This method of measuring the peak power is not likely to be very accurate, but it is, if anything, under-representing the amplitude of the peak power of this signal. It's interesting to note that these clicks seem to come in pairs, separated by 12-13 samples (approximately 1 millisecond - about the distance that it takes a radio signal 300 km/186 miles) - and this "double pulse" has been observed over several days. This double pulse might possibly an echo (ionospheric, ground reflection), but it seems to be too consistent. Perhaps - related to the theoretical possibility of this being some sort of HFT transmission - it may be a means of validation/identification that this pulse is not just some random, ionospheric event.

Listening to it yourself:

Again, if you wish to listen for it, remember that it is an unmodulated CW carrier (except for the "clicks") and that you should turn all noise blanking OFF. Using an SSB filter, these clicks are so fast that they may be difficult to hear, particularly if the signal is weak. So far, it has been spotted on 14.378 and 14.390 MHz (try both frequencies) which means that in USB, you should tune 1 kHz lower than this (e.g. 14.377 and 14.389) hear a 1 kHz tone. Once you have spotted this signal, switching to AM may make hearing the occasional "click" easier.

Remember that depending on propagation, your location - and your local noise floor - you might not be able to hear this signal at all. Keep in mind that the HF bands are pretty busy, and there are other signals near these two frequencies with other types of signals (data, RTTY, etc.) - but the one in question seems to be an (almost!) unmodulated carrier.

It's likely that this carrier really isn't several hundred kHz wide, so it may not actually be getting into the top of 20 meters, but the peak-to-average power is so high that it may be audible on software-defined radios: Because the total signal power across 20 meters may be quite low, the "front end AGC" may increase the RF signal level to the A/D converter and when the "click" from this transmitter occurs, it may cause a brief episode of clipping, disrupting the entire passband.

* * * * *

If anyone has any ideas as to what this might be, I'd be interested in them. If you have heard this signal and have other observations - particularly if you can obtain a beam heading for this signal, please report them as well in the comments section, below.

Updates:

- November, 2022: As a follow-up, it would seem that the nature of this "clicky carrier" has changed very slightly. It appears

as though the bandwidth of the "click" is now better-contained and is

only a few 10s of kHz wide rather than around 100 kHz wide.

It also appears that other frequencies are being use - including 14.372 MHz. More frequencies may be used routinely, but I don't monitor this signal frequently.

- December, 2022: This type of signal was noted on 14.380 MHz - and possibly 14.413 MHz simultaneously, making for a total of at least four frequencies where this type of signal has been observed.

- July, 2023: This type of signal was noted at 14.413 and 14.446 MHz - "clicks" and all. Since the previous update, other frequencies have been noted - singly and simultaneously in the same general area.

- November, 2023: These same carriers have been observed elsewhere, specifically below the 40 meter amateur band. Frequencies where these have been noted during the North American nighttime and evenings include 6.810, 6.832, 6.861 and 6.938 MHz. Other frequencies where these have been observed include 9.081, 9.107, 9.170 and 9.229 MHz. There are, no doubt, other frequencies at which these carriers may be found during various times of day and to accommodate always-changing propagation and interference - plus it is likely that frequencies are changed frequently... because.

- Related to the above: A proposal to modify FCC Part 90 was made by a group with an interest in High-Frequency trading via the 2-25 MHz frequency range using ionospheric propagation. This proposal may be read here: https://www.fcc.gov/ecfs/document/1042840187330/1

This page stolen from ka7oei.blogspot.com.

[End]