|

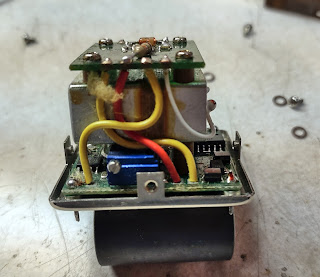

Figure 1:

The 10 MHz OCXO (lower right) in use with my homebrew

24 GHz transverter. At 24 GHz, the oven provides excellent frequency

stability, suitable for SSB or even digital modes, while providing a

frequency uncertainty of a few hundred Hz at most.

Click on the image for a larger version. |

Why a frequency reference?

When operating on the microwave amateur radio bands, narrowband

modes

(such as SSB or CW) are often used to maximize the link

margin - that is, to be able to talk when signals are weak - and

when we use microwave frequencies

and narrowband modes such as SSB or CW

one must maintain pretty good frequency stability

and accuracy:

- Stability is important as a drift of even a few hundred Hz

at the operating frequency (in the GHz range!) can affect

intelligibility of voice - or, if CW is being used for

weak-signal work, such drifting can move the received signal

outside the receiver's passband filter! Having to

"chase" the frequency around is not only distracting, but it

complicates being able to communicate in the first place.

- Accuracy is also important because it is important that

both parties be confident that their operating frequencies

are reasonably close. If a contact is arranged

beforehand it is vital that both parties be able to find

each other simply by knowing the intended frequency of

communication and as long as the two parties are within

several hundred Hz of each other it is likely that they will

be able to find each other if the path "works" in the first

place. If the error was on the order of several kHz,

"hunting" would be required to find the signal and if those

signals are weak, they may be missed entirely.

Because achieving such stability and accuracy requires some

effort, it is more convenient if our gear is constructed such

that it can use a common, external frequency reference and lock

to it. In that way, we need only have one "master"

reference rather than several individual references.

|

Figure 2:

The 10 MHz Isotemp 134-10 OCXO - one of many similar units that

often show up on EvilBay. A 200uF, 16 volt capacitor is soldered

directly to the supply terminals of the OCXO to provide low-impedance

filtering of any noise that might appear on it - any value from 2000 and

up (to several thousand uF) would be just fine. The green device is a 10-turn

trimmer potentiometer soldered directly to the OCXO's pins. This

potentiometer is used to adjust the tuning voltage to precisely set the

frequency and locating it at the OCXO practically eliminates the possibility

of external noise pick-up on the tuning lines and the possibility of the I*R

drop on the wires causing a slight tuning shift as the oven power changes.

The OCXO is mounted in the case using rubber/metal shock mounts with "blobs"

of RTV (silicone) on the sides that prevent it from hitting the inside of the box

should the unit be accidentally dropped.

The corners/edges of the OCXO could be mounted in some stiff foam,

instead - but it should not be thermally insulated by this foam unless you have

demonstrated to yourself that doing so will not reduce the oven's stability.

Click on the image for a larger version. |

Having one

common frequency reference can also be

convenient if one is operating portable using battery power

since it can mean that one doesn't need to keep all of those

individual pieces of gear "warmed up" all of the time to

maintain stability. If a particular piece of gear can

accept an external 10 MHz input, this would allow one to turn on that gear

(and

drain battery power) only when it is needed.

At this point I might mention that Rubidium frequency references

(such as one described here)

are also readily available in the surplus market as well that

provide at least an order or magnitude greater accuracy and

stability and warm up in less time than the crystal reference,

so why not

always use a Rubidium reference

instead of a crystal-based one? The crystal-based unit is

cheaper, easier to package and consumes significantly less power

than a Rubidium reference, and the stability/accuracy of a

good-quality

crystal-based reference is more than "good enough" through at least 24 GHz. When I go out in the field to do portable

microwave work I'll often power up the OCXO after putting it in

the car knowing that by the time that I get to my destination

and set up, it will be warm and on-frequency.

(To be sure, I bring a Rubidium reference as a "backup"!)

About this frequency reference:

The oscillator:

The goal for this project was to have a "reasonably stable and

accurate" reference: Based on an Isotemp OCXO 134-10 this particular unit has a rated stability of about +/-1.0x10

-8 (+/-1 Hz at 100 MHz) or better after it has warmed up for a while with short term variations approaching +/-1.0x10

-10 (+/-1 Hz at 10 GHz). In-field observations appear to confirm this stability with tests having shown that this

unit seems to be able to hold the 24 GHz local oscillator to

within 500 Hz or better with no obvious frequency "warble" once it has had 15-20 minutes or so to

warm up - and it seems to be fairly stable across a range

ambient temperatures from "hot" to "below freezing." The

Isotemp unit - and others like it - are readily available on

both the new and surplus markets, available via EvilBay and

similar and other than having different voltage and stability specifications, they, too, can be integrated into a stand-alone project such as this.

The oven module itself is rated to operate from 13 volts, +/- 2

volts, implying a minimum of 11.0 volts. Even though

testing indicated that it seemed to be "happy" with a supply

voltage as low as 9.8 volts or so, it was decided to adhere to

the published specifications and in looking around I noticed

that most readily-available low-dropout regulators

(and those

that I had onhand) were not specified to handle the maximum

"cold" current of this oven - about 800 mA - so I had to

"roll my own" 11 volt "zero-dropout" regulator.

More on alternative regulators, below.

|

Figure 3:

The inside of the enclosure containing the OCXO, regulator and driver.

On the left is the shock-mounted OCXO while the circuit on the perfboard

is the "zero drop-out" regulator and the 10 MHz distribution amplifier.

The P-channel FET pass transistor can be seen along the top edge of

the die-cast enclosure, bolted to it to dissipate any heat while along

the right edge, inside the enclosure is a piece of glass-epoxy circuit

board material to provide a solid, solderable ground plane for the

distribution outputs and the DC input filtering. |

A "zero-dropout" regulator:

Why regulate? I noted in testing that slight variations of

supply voltage

(a few hundred millivolts) would cause measurable

disturbances in the oscillator frequency due to the changes of

the power applied to the heater, taking several minutes to again

reach

(thermal?) equilibrium. Since battery operation was anticipated,

it is expected that the supply voltage would change frequently between periods of transmit and receive - as well as due to

normal battery discharge. Because I had chosen to use an OCXO that required

(at least) 11.0 volts to be run from a "12 volt" lead-acid battery, I needed a circuit that would reliably produce that 11.0 volts even when the battery voltage dipped below 11.5 volts - as it could during heavy transmit loads and the end of a power cable with the battery near the end of its charge.

Referring to the schematic U101, a standard 5 volt regulator

(the lower-power 78L05 is a good choice) provides a stable

voltage reference for U103, a 741 op amp, which is used as an

error amplifier. A 7805 was chosen as it is

readily-available but a Zener diode and resistor could have been

chosen: If a Zener is used, a 5.6-6.2 volt unit is

recommended with 2-5 milliamps of bias as this voltage range

offers good temperature stability.

If the output voltage is too low, the voltage on pin 3

(the non-inverting input) drops, along with pin 6, the op amp's output which turns on

Q103, a P-Channel power MOSFET by pulling it's gate toward ground, which increases the voltage and

once the voltage on the wiper of R119 reaches 5 volts - that of

the reference, which is applied to pin 2, the non-inverting input - the circuit comes to equilibrium. A

P-Channel FET

(a slightly less-common device than an N-channel) was used because it takes

3-5 volts of drain-gate voltage to turn on a FET and it would

have been necessary to have at least 3-5 volts

above the power supply

(about 16 volts) to bias the

gate "on" if an N-Channel FET were used whereas we can pull the gate voltage "down" from the supply voltage with a P-channel device. Furthermore, with the

use of a P-Channel power MOSFET the dropout voltage of the

regulator is essentially limited to the channel resistance of

the that FET. In theory a PNP

(possibly a complimentary pair

arrangement) could be used instead if one can tolerate closer to

a volt of dropout, but the FET was chosen to minimize the

dropout voltage.

In testing, once the oven was warm

(a condition in which the

OCXO was drawing approximately 250 mA at normal "room

temperature") the dropout of the regulator was approximately 50

millivolts - a voltage drop that is a result of the resistance of the wires used to power the unit and the on-resistance of the FET. This rather simple

regulator seems to work quite well, holding the output voltage

steady to within a few millivolts over the input voltage range

of 11.1 to 17 volts with good transient response.

|

Figure 4:

The end panel of the OCXO module. The power feedthrough/capacitor

is on the left, obscured by the red/white power cable with the yellow-ish

"ready" light to the right of it. The three BNC connectors are the 10 MHz

outputs, allowing multiple devices to be connected while in use and/or while

its calibration is being checked.

Click on the image for a larger version. |

"Faster warmup" feature:

This OCXO has a "status" output that, when "cold", outputs about

0 volts and in this state, Q101 is turned off, allowing R112 and

R113/D102 to pull its collector high - turning on Q102 - which

pulls the gate of Q103 low through R118, turning it fully

"on." In this state the voltage applied to the oven is

nearly that of the battery supply and this higher voltage

increases the power applied to the oven, allowing it to heat

more quickly. Once the oven's "status" line goes high,

Q101 is turned on, illuminating the LED and turning off Q102,

allowing the regulator to operate normally.

Note: When the unit is warming up, the

OCXO's voltage is unregulated which means that the supply

should be kept below 15.0 volts to stay within the "safe zone"

of the ratings of the oscillator itself.

Does the "boosted" voltage actually help the oven warm up

faster? Probably only a little bit, but it took only 4 additional

components to add this feature!

Status indicator:

It should

be noted that this status line

doesn't indicate that

the oven has

fully

warmed up, but only that it's

still warming: At

"room temperature" it takes at least another 5 minutes before

the frequency will be stable enough for use and another 5

minutes or so

after that until it's "pretty close" to the

intended frequency and it can be used at microwave frequencies

without others having to chase you around.

Why have the

indicator light if it doesn't indicate that the unit is

actually "ready"? While this indication isn't perfect if the light

isn't on, you can be sure that the

frequency output

won't be valid for one reason or

another.

Because the OCXO itself is somewhat load-sensitive

(about +/-1.0x10-9 - perhaps a few 10s of Hz at 24 GHz) U102 - an

LM7171 - is used as a distribution amplifier to both isolate the

oven from its loads and to provide fan-out to allow multiple

outputs to be driven simultaneously. The LM7171, a

high-output, high-speed op amp, is configured for a gain of 2,

providing about 2 volts peak-to-peak output with the drive

provided by the OCXO.

Mounting the oven:

Because this unit is intended to be used "in the field" it was

decided to mount the OCXO module itself to prevent mechanical

shock from affecting the reliability, frequency stability and

accuracy and this was done using some rubberized mounting

pillars from scrapped satellite equipment while some "blobs" of

silicone were placed on the wall of the die-cast enclosure to

prevent the OCXO housing itself from directly impacting it

should the unit be accidentally dropped.

|

Figure 5:

Schematic of the OCXO-based unit, including the zero-dropout regulator and 10 MHz distribution amplifier. It is important that the connection of the "ground" side of the 10 turn calibration potentiometer be made at the OCXO and not elsewhere, this to minimize possible frequency shifts due to I*R losses as the oven's heater power changes. The diagram shows a

value of 82 ohms for R108-R110 because that what was easily found when it was constructed (and it really doesn't

matter much) but anything between 47 and 100 ohms will be fine, based on your preference.

Click on the image for a larger version. |

A few bits of stiff foam could also be used to provide some

shock mounting in the corners of the OCXO but be aware that

some

oven-based oscillators have been known to become

less

accurate and stable if they are

over-insulated and can't radiate at least

some of their heat, so don't go

overboard.

Important:

Like any crystal oscillator, it is somewhat "position sensitive"

in that a frequency shift of 10s of Hz

(at 24 GHz) can

be observed if the unit is placed on its side, upside-down,

etc. due to the effect of gravity on the quartz crystal itself. While this effect is very minor, it's worth noting

when it's being set to frequency and in operation.

In other words, when you calibrate it (see below) do so in the same physical orientation that it will be when it is in use.

DC input protection and

filtering:

The input supply is RF-bypassed using a feedthrough

capacitor to prevent the ingress or egress of extraneous RF

along the power lead. For power-supply short-circuit

and reverse-polarity protection, R101, a 1.1 amp, self-resetting

PTC fuse is used in conjunction with D101, a 3-amp diode.

Why not use a forward-biased diode for reverse-polarity protection? If you recall, we are going through the trouble of minimizing voltage drop-out with our "special" voltage regulator and we could diminish this if we inserted something that caused a voltage drop - even the 0.3-ish volts of a Shottky diode would undermine this effort.

By using the "reverse-biased diode" and the self-resetting PTC fuse we get:

- A means of current limiting should something to wrong: If we accidentally short something out, the fuse resets itself when the fault is cleared - and no need to worry about not having a spare fuse when one is out in the hinterland trying to operate!

- If the polarity is somehow connected backwards, the diode will conduct and the PTC fuse will "open" - no harm done, returning to normal once the fault is rectified.

- There is minimal voltage drop related to the fuse as its resistance is a fraction of an Ohm under normal conditions which means that we won't compromise the voltage "headroom" of a 12-volt lead-acid battery.

Calibration:

The

best way to calibrate this device is to use a GPS disciplined

oscillator or a known-good rubidium frequency reference. If you have

access to one of these, connect the output of the OCXO to one channel of

a dual-trace oscilloscope and the known-good frequency reference to the other,

triggering on

one of two signals - it really doesn't matter which one.

Note: If you have an analog dual-trace oscilloscope with sufficient bandwidth you can use the "X/Y" mode to produce a Lissajous pattern (obligatory Wikipedia reference here) - but this doesn't always work well on modern, digital scopes when high frequencies are involved due to sample aliasing.

Adjusting the 'scope to see one of the waveforms, one should see a stationary wave

(the one on which the 'scope is triggered) while the other will be "sliding" past the first. Adjust the OCXO's frequency

(after the OCXO has warmed up for at least 30 minutes - preferably more) while it is sitting in the same physical orientation in which it will be used as this can

(slightly) affect frequency. To assure a more consistent thermal environment it is suggested that the cover of the enclosure containing this circuitry be left on except during the brief periods to access the 10-turn potentiometer unless provisions are made to access it

(via a hole) from outside the box.

The OCXO's frequency is then adjusted to

minimize the rate at which the two waveforms are

moving

with respect to each other: It's sometimes easier to make this

adjustment if the 'scope is adjusted so that the two waves are atop each

other and about the same size. With careful adjustment it should be

possible to set the frequency so that the two waveforms that take more than 10 seconds to "slide"

past each other - maybe longer. The Isotemp OCXO should, in

theory, be able to hold to that "10 second" slide rate over a wide

variety of temperature conditions.

If you

don't

happen to have access to a rubidium reference or a GPS Disciplined

oscillator, you can do "reasonably" well by zero-beating the 10 MHz

output with the signal from WWV or WWVH, be note that Doppler shifts can

cause their apparent frequencies to shift by 1 Hz or more.

I'll leave the explanation of methods of successfully zero-beating an off-air signal to others on the GoogleWeb.

The best time to attempt this is when you are hearing

only one of these two stations

(assuming that you can ever hear them both)

and when it's signal is the most "solid" - that is, it's fading in and

out is at minimum. Often, the worst time to make this sort of

measurement is when

any part of the radio path

between you

and WWV

(or WWVH) is within a hour or two of sunrise or sunset as this is when

the ionospheric layers are in a state of flux. If you are hearing

both WWV and WWVH, don't try this as the two frequencies and signal strength will not likely be consistent and the results will probably be confusing.

If

you don't happen to live in an area where you have a reasonable signal

from WWV or WWVH then I suggest you ask around to find someone who has

appropriate gear to help with this task.

Comments about alternative schemes for low-dropout regulation for the OCXO:

There are a number of "low-dropout"

adjustable regulator ICs on the market that

may be suitable for your this project - but there are a few caveats.

For example, there is the Linear Technologies LT1086-Adj which is rated

for up to 1.5 amps of current. While lower dropout than a

conventional adjustable regulator such as an LM317, it does have

approximately 1 volt of dropout which means that if you set the OCXO's

supply voltage to 11.0 volts - the minimum recommended in the

OCXO's specification - your battery voltage must be at least 12.0 volts:

While this represents a lead-acid battery that mostly depleted

it is likely that a small, but healthy, lead acid could drop to such

a voltage under transmit load - particularly if the resistance of power

leads is taken into account. This 3-terminal regulator is used in

a manner very similar to the LM317 - except that you

really must have some good quality, low-ESR capacitors

(probably tantalum) very close to the regulator itself -

see the data sheet.

Also made by Linear Technologies is the LT1528 that is rated for up to

3 amps that has a

(nominal) 0.6 volts of dropout - more typically in

the 0.3 to 0.5 volt area for the amount of current consumed by the

OCXO, particularly once it has warmed up: This extra margin would

keep one in the "safe" region of the OCXO's operating voltage range

down to around 11.5 volts from the batter allowing both "deeper" discharge and

more voltage drop on connecting wires. This part is somewhat

more complicated to use than the LT1086, above, but it is, overall,

simpler than the op-amp based regulator described earlier in this page.

If the "fast warmup" were to be implemented on either of the above

regulators it would take a different form than the above - likely using

several resistors and a transistor or two to "switch" the

resistor-programmed voltage setting to something higher than the normal

voltage.

There are a number of other, similar, low-dropout regulators that are

made by different manufacturers, but very few have as low a dropout voltage

(e.g. about 50 millivolts) as

the simple FET/Op-amp circuit described on this page.

Additional comments:

- It is recommended that one not use a switching regulator to power the OCXO unless

it has been extremely well filtered and bypassed. Unless such a regulator is a buck-boost type it will probably have a higher drop-out voltage than even a standard low-dropout linear regulator. Because of the rather low overhead voltage involved, there is not much loss in the linear regulator - only 10-15% or so with a 12.5 volt supply with a 11.0 volt output - a loss comparable to a garden-variety switching regulator.

- If you are interested in an

example of this project being built with an etched PC board

with surface-mount parts, visit VK4ABC's 10 MHz OCXO Web Page.

* * *

This is a revised version of one of my web pages, the original being found at http://www.ka7oei.com/10gig/10meg_oven_1.html

[END]

This page stolen from ka7oei.blogspot.com

Note: This post is partially an attempt to test means of reducing the "scraping" of content of this blog by sites such as "rssing", who seem to "swipe" content and "load" search engines' result with unwary readers NOT ending up at my page. xe2XV6SJ9914C50H08S8 QY2IU7TU0C11c57804Q8

xe2XV6SJ9914C50H08S8 QY2IU7TU0C11c57804Q8