|

| Figure 1: The Marantz 2110 with the now-functioning scope. Click on the image for a larger version. |

The 2110 is a medium-to-high end FM/AM broadcast receiver from the early/mid 1970's and it is equipped with a small oscilloscope for a tuning aid as much as "ooh's and ahhs." It had been given to me in a semi-non-working condition by a friend of mine a few years before and all it really needed at the time was a thorough re-alignment and a cleaning of switches and it was back in working order.

In addition to the 'scope having an external X/Y input to set the phasing of external audio gear (e.g. tape recorders, etc.) this receiver will also show two-channel stereo (or mono) audio with the 'scope's X/Y channels being fed by the tuner's own two audio channels: On mono broadcasts, a diagonal line of varying lengths is displayed, slanting from upper-right to lower-left (as can be seen in the above photo) and with stereo reception one sees a semi-random field of lines with the same general slant: If, somehow, the phase of one channel were reversed, the slant of the line would also be reversed (top-left to bottom-right.)

For tuning, the 'scope display is a bit different: On AM, a short horizontal line simply goes up and down, the vertical height being related to the signal strength. On FM, the horizontal position of a short vertical bar (with respect to the center) represents how well the signal is tuned: If the small bar is to the left, the tuning dial is low in frequency and vice-versa if it's high. The vertical position of the small bar also indicates signal strength of FM, but it also indicates something else: It will show residual AM, and the more of this, the longer this bar will get.

Recall the difference between AM and FM: On the latter, the signal strength does not change with the audio - or at least it shouldn't! If it does, this might be a result of one or both of the following:

- Mistuning of the signal puts a portion of it partway off-frequency. In that case, as the FM signal wobbles up and down in frequency with audio, part of it may go outside the receiver's filter so less is intercepted, the result being that the signal level as "seen" by the receiver changes.

- Multi-path distortion. If there are multiple reflections of a signal due to buildings, mountains, etc. the signal strength of multiple reflections can either reinforce each other or cancel each other out. As it happens, these effects can be frequency-sensitive and wobbling of the frequency up and down with audio modulation can cause the varying reinforcement/cancellation and also affect the signal strength at the receiver.

So, on FM, the scope is most useful for making sure that the receiver is tuned in the dead center of the received signal - especially important since this receiver doesn't have an AFC - Automatic Frequency Control - to "lock" it on frequency to compensate for the inevitable drift as it warms up.

Back to the 'scope.

But first:

The obligatory warning about high voltage:

The voltages found in this receiver - particularly those around the mains power supply and the oscilloscope - are potentially lethal!!!

If you aren't familiar with the safety precautions and techniques related to high voltages

If you aren't familiar with the safety precautions and techniques related to high voltages

you have NO BUSINESS messing with them!

Before final replacement of the transformer, check the high-voltage capacitors and diodes to make sure that they are in good shape - possibly preemptively replacing them: It may have been a failure of one of these components that caused the original transformer to fail. If you are really lucky, one of these components failed and the transformer may be fine!

I can take no responsibility for any damage or injury that might result from anyone attempting to use the techniques described on this page! While these techniques may be applicable to other tuners/devices with built-in oscilloscopes, you are on your own to do the necessary legwork to determine that device's requirements!

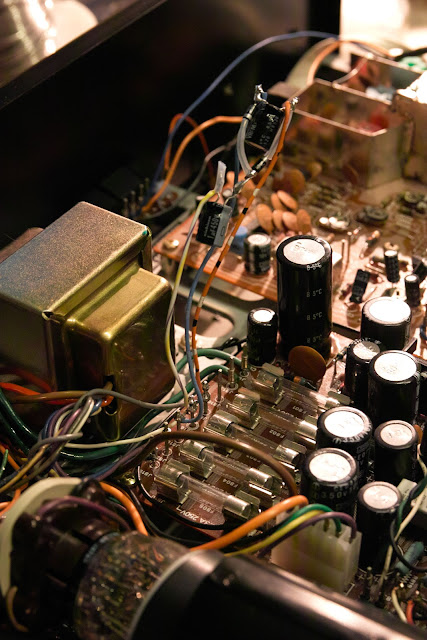

When the scope flickered out for good I popped the cover off the receiver and wielding a voltmeter and a somewhat fuzzy copy of the service manual that I'd found online I was chagrined to note that all of the several voltages coming out of the scope's power supply transformer were missing, indicating that the primary winding had failed open: Unsoldering of the relevant primary wires for the transformer and a subsequent ohmmeter check verified this.

I could have probably come up with some sort of modern switching supply circuit to generate the needed voltage - possibly from a something found on EvilBay - but these sorts of voltage converter modules all have one thing in common: They produce fairly high amounts of electrical noise at ultrasonic frequencies. From past experience I knew that if I put one of these devices inside the tuner it would be nearly impossible to keep it from getting into the receiver's other circuits and causing some sort of interference - particularly the AM tuner! (I don't use the AM tuner much, but still...)

After using the receiver "scopeless" for over a year I decided to see what I could do to effect a replacement so I removed the dead transformer and did a bit of research and found that, as expected, it was a common item to fail and a direct replacement was essentially unobtainable. In disassembling the transformer far enough to determine that not only had the "inner" connection of the primary winding failed, I also determined that I wasn't going to get the transformer apart far enough to rewind the primary without damaging the other windings.

|

| Figure 2: A re-drawn portion of the original Marantz's Scope Power Supply Wiring. The fuses on the power supply board are not shown. Click on the image for a larger version. |

If I wanted the 'scope to work again, I'd need to find a replacement of sorts!

According to the service manual, what I ultimately needed were the following (nominal) DC voltages as best as I could discern from the fuzzy drawing:

- -601 volts for the CRT's cathode.

- +186 volts for the vertical and horizontal deflection amplifiers.

- 6.4 volts AC for the CRT's filament, and this winding had to be isolated so that it could "lifted" to the -601 volt CRT cathode potential.

In looking online at a number of different transformers I ordered a possible replacement from Antique Electronics Supply: Not an exact replacement, mind you, but one that could have been made to work - but it turns out that I should have looked in my own transformer collection first!

When I looked in my "box o' transformers" I found that I had a several Thordarson T-63041-1CB transformers in my collection that I'd acquired at some point in the unknown past and although I have yet to find official specifications for this device on the web, I also discovered, in the same box with the transformers, a note detailing what I had found several years before when I'd reverse-engineered it using an ohmmeter to determine the likely windings and then the careful application of AC voltages through a "Variac" (tm) type autotransformer. Based on what few specifications were on the transformer's label (e.g. its primary voltages) I was able to figure how to safely apply power to its primaries (it has two!) and then measure the secondary voltages. As it so happens it had not only an isolated secondary that measured 6.6 volts (unloaded!) but also one that measured 180 volts.

Figuring that I could make something of this transformer, I set to work!

|

| Figure 3: The transformer used as a "replacement". Most importantly, it has an isolated 6-ish volt filament winding! Click on the image for a larger version. |

This transformer was slightly smaller in height and width than the original, and a millimeter or so "thicker" but it looked as though I could cram it in the original transformer's metal casing.

First, I drilled a hole one of the original transformer's side (called the "bell") covers (and filed it to smooth the sharp edges) to allow access to the secondary winding's wires as this transformer had wires coming out of both sides of the winding face instead of the front and back as per the original. I then centered the transformer in the original side covers and was able to "gently force" the transformer into the U-shaped mounting bracket after bending it to accommodate the slightly thicker transformer. Holding everything in a vise, I was able to attach the bottom cover and bend the original cover's tabs into place, using a screwdriver to align them and when I was done, the "new" transformer didn't look much different from the original! Using the original case - and its implied shielding - is often important as it prevents the magnetic field from the transformer from affecting the trace of the oscilloscope!

Now, to make both +186 volts and -601 volts out of a single 180 volt winding!

As we can see from the drawing in figure 2, individual windings - all referenced from the center-tap - were used on the original transformer to produce the high voltages. In this case, a pair of 166 volt windings, center-tapped, were used to full-wave rectify and produce the nominal +186 volt DC supply for the scope's deflection circuits. On one side of the center tap we also see a 430 volt winding that was half-wave rectified to produce the -601 volt which was then filtered by a series pair of 10uF, 350 volt capacitors - and this voltage was applied to the floating 6.4 volt filament windings.

Fortunately, there's nothing here that overly complicates the ability to generate these same voltages via an alternate means, and as it turns out we can use our new-found transformer's 180 volt winding to generate both of these these voltages. Generating the +186 volt supply is trivial: Simply ground one end of the 180 volt winding and half-wave rectify it - and this produces roughly +180 volts DC, just what we need! See figure 5.

Generating the -601 volt supply is a bit trickier - but not overly so: By using a small assortment of capacitors and diodes we can take that 180 volt AC waveform and multiply it several times to produce the desired voltage. In this case, we use a voltage "tripler" which takes advantage of the peak voltage of the 180 volt winding so that the actual "AC-Input to DC-output" voltage ratio is closer to 3.8 than 3 and this just happens to yield a voltage very close to our nominal -601 volts, or around -615 volts (under circuit load) as depicted in the drawing above. To our advantage, we need very little current to supply the CRT's cathode which allows us to use rather small-value (1 uF) capacitors as depicted below.

As it happens, some of the circuitry required for a tripler is already included in the original Marantz power supply, namely the last diode and capacitor on the far right of figure 4 and this means that we don't need to build all of the circuity above (but if we did, it wouldn't hurt...) so we end up with the final schematic shown in figure 5.

As seen in the drawing the filament supply connects to J819/J820 in the same manner as the original since we have the same "floating filament" winding arrangement as the original transformer. We don't have a center-tapped transformer, so we simply connect one end of the 180 volt winding to the system ground (J816) while the other end of the transformer connects to either J815 or J817 (or both, if you really want) but it doesn't matter which, since we are using a half-wave rectified circuit instead of the original center-tapped full-wave!

Even though our new transformer's winding produces 180 volts AC instead the 166 volts AC of the original, our DC voltage is ultimately about the same due to the half-wave rectification. Our power supply is still "clean enough" in terms of AC ripple since the capacitance on the original power supply board (10uF) is more than adequate.

In figure 6 we can see these components assembled, hanging in free space on the wires - along with insulating tubing on the component leads - connected into the circuit. If you look carefully at both the picture and the drawing above you'll note that it connects in only three places:

- The "ground" (bottom of the capacitor in the box) goes to J816 - the main system ground..

- The "input" (180 volts AC) goes to J815 and/or J817 - the same terminal that the "top" of the 180 volt winding was connected.

- The "output" of the circuit connects to J818 where the original 430 volt winding connected.

I measured about +175 volts where +186 volts should have been (close enough!) and -617 volts where -601 volts was to be (pin 1 or 2 of J914). It's worth mentioning that if you measure the voltage at J818, you won't see the -600-ish volts since the rest of the multiplier circuit (e.g. the last diode and capacitor) is on the board, which is why you'll see the -600-ish volts only at J914! Carefully measuring the filament voltage (which is at -600 volts with respect to the chassis!) I observed 6.3 volts or so - a slight drop from the "unloaded" 6.6 volts measured above and just perfect for the CRT filament!

To complete the circuit I added a bit of extra insulation to some of the wires connecting the capacitors and diodes (I used some craft paper, taped together) so that they could not touch when the piece of heat shrink tubing that was slid over the above was shrunk, compressing components and leads together. Finally, the module was completely enclosed in shrink tubing and attached to the brown wire from J914 with a single nylon wire tie to keep it in place as can be seen in figure 6.

Taking my own advice, I also checked the two 10 uF, 350 volt series-connected capacitors that filtered the -601 volt supply. When powering up, I (carefully) measured the voltage across each capacitor and while half the power supply voltage should have been across each capacitor, I noticed that there was about 400 volts across one and 200 volts across the other indicating that at least one of them had a problem! Unsoldering them from the board (after first having disconnected the power and shorting them out to discharge the remaining voltage!) I noticed a small amount of crust on the board as well as some corrosion around the capacitors' leads indicating that they were leaking electrolyte.

After replacing them with a pair of 33uF, 400 volt units I saw that the voltages across each capacitor were within 10-20 volts of each other. Practically speaking, a capacitor value as low as 1 uF would probably suffice, but all I had in that voltage range were the 33uF units mentioned. These two capacitors, when replaced, should be identical and from the same batch, if possible. Normally, high-resistance (330k-680k) resistors are placed across series-connected capacitors to equalize the voltage, but that was not done in this case: Next time I have the receiver apart I will add those to the bottom of the board - just to be safe!

Running the receiver for several hours I observed that the transformer doesn't get any warmer than the ambient temperature within the receiver itself. I seem to recall that the original transformer ran a bit warm indicating that it was either already somewhat faulty or, more likely, that it had originally been under-designed with too-few turns on its primary and causing it to run a bit warm (a cost-savings measure, no doubt!) and possibly leading to its ultimate failure.