Having wound the choke described in the

previous installment about chokes - (link) - I decided to proceed with the next logical step in the project: Winding a filament transformer. Also see the follow-on article

Part 3 - The Plate (High Voltage) Transformer - (link).

With the lower voltage requirements, the filament transformer is the next-easiest since being a

step down transformer, fewer turns are required overall and the wire sizes will be larger.

The first step was to figure out my voltage and current requirements - but this was already known in the form of the filament requirements of the tubes to be used: Two center-tapped windings, each capable of 11 volts at 11 amps. To calculate the necessary winding parameters

(e.g. number of turns, size of wire, etc.) I will refer again to the two links noted in the previous installment, included below:

- Turner Audio (link) - These pages contain much practical advice on power and audio transformers and chokes. (Refer to the link "Power Transformers and Chokes" (link) and related pages linked from that page.)

|

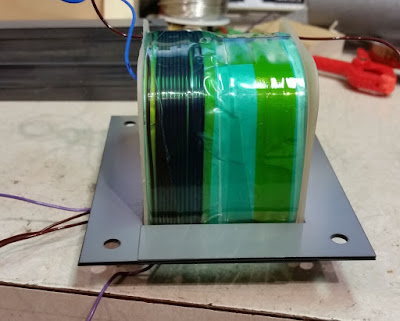

Figure 1:

The completed filament transformer, before varnishing,

ready for testing.

Click on the image for a larger version. |

- Homo-Ludens - Practical transformer winding (link)

- While mostly about power transformers, this page also contain

practical advice based on hands-on experience of winding, re-winding and

reverse-engineering/rebuilding transformers. There is also another

linked page "Transformers and Coils" (link) that has additional information on this topic.

While there are enough equations and general information spread across both pages to provide the necessary information if you want to crunch numbers with equations, of particular interest is a spreadsheet found on the Homo-Ludens "Practical transformer winding" web page that allows one to "play" with various configurations. For this spreadsheet we will need to input what we already know, such as:

- Input voltage: 120 VAC (nominal) at 60 Hz. Since we want to have multiple taps to fine-tune the voltage, we'll also calculate for 115 and 125 volts.

- Output voltage: 11 volts under load. A rule of thumb is to add 5% to this to accommodate various losses so this would be (11 * 1.05 = 11.025) or approximately 11.5 volts.

- Output current: 22 amps - the sum of the two 11 amp filament windings. They will be "split" in later calculations.

- Core size: E150. The Edcor core and bobbin that will be used has a stack height of 38mm and a center leg that is 38mm across.

- Set a design goal for wire sizes corresponding with a current density of 0.4 mm2/amp, a rather conservative number.

- Let us initially set a "fill factor" of 0.4 - more on this parameter, later.

- Core material information: The Edcor laminations use M-6 GOSS (Grain-Oriented Silicon Steel) which is a material that is capable of safely handling higher magnetic flux than "generic" iron cores. This has two important implications:

- The saturation flux of this material is in the area of 1.7 Tesla. This is a very "soft" number, dependent largely on how much core heating one is able to tolerate in the intended application.

- The iron loss (in watts/kg at 1 Tesla) for the M-6 material is quite low - approximately 0.5 watts/kg@1T (at 50 Hz) versus 2 watts/kg@1T for "generic" transformer iron. The spreadsheet expects the 50 Hz value here regardless of the actual frequency.

A few words about the wire size:

The value of 0.4mm2/amp target that I chose is fairly conservative based on the recommendations found in several sources:

- The Turner Audio site suggests a value of (3 amps/mm2) = 0.33mm2/amp as a general number.

- The Homo-Ludens site suggests a value of 0.35mm2/amp for "medium-sized" transformers (50-300 watts) wire such as this and smaller/heavier (0.25 and 0.5mm2/amp) conductors for very small and large transformers, respectively.

- Various vintages of the ARRL Amateur Radio Handbook note that a value of 1000 cma (0.506mm2/amp) as being "conservative" with a value of 700 cma (0.354mm2/amp) being suggested for typical use.

- Interestingly, the 1936 Jones Radio Handbook notes recommends a 1000 cma

(0.506mm2/amp) value for typical amateur use and increasing this to 1500 cma (0.759mm2/amp) for transformers that would be intermittently subjected to significant overload and/or were in hot, poorly ventilated environments. These recommendations are understandably based on the use of older materials such as paper insulation and the more fragile varnished/enameled wire of the day.

- If one peruses the Edcor site one can glean bits of data here and there and they mention a design goal of 500 cma (circular-mill amperes) which converts to 0.253mm2/amp. (Reference: Tek Note 43 - link.) When I read this I presumed that this recommendation may have been intended for small, low-power transformers, but I noted this posting - link in their forum where a current of 200mA is mentioned being used with 30 AWG wire which calculates to 0.254mm2/amp.

Even more about flux density:

- As noted, for inexpensive, generic cores of unknown properties Turner Audio suggests a maximum flux of 0.9 Telsa while the Homo-Ludens site suggests that 1.0 Tesla is "probably OK" for the vast majority of cores of unknown provenance. The later site recommends that if these cores are being re-used that one counts the number of turns on the original primary (if it is being re-wound) and use this, along with the core's cross-sectional size and the original primary voltage and frequency to estimate the original flux density.

- The M-6 material is capable of much better performance (e.g. lower loss) than "generic" iron - likely being usable at 1.6-1.7 Tesla, but Edcor mentions in Tek Note 43 (linked above) that their design goal is 1.4 Tesla - value with which both the Turner Audio and Homo-Ludens sites agree as being appropriate for this higher-quality material. Based on typical curves for M-6 material, this would seem to be a reasonable compromise between higher core losses, fewer turns (e.g. higher flux) and more turns with higher copper losses, lower core losses (lower flux).

Based on the above I decided to use 1.4 Tesla as the target in my design.

Comment:

If you are keeping the original primary winding of a re-used transformer, wind a few

dozen turns of hookup wire and carefully measure the resulting, unloaded

voltage. Comparing this with the applied primary voltage and taking

the number of temporary turns that were wound the number of turns on the

primary may be quite accurately determined and from there, along with

the stack height and center leg size, it should be possible calculate the approximate magnetic flux of the original device. Regardless, if you are operating the original primary at its design voltage, you can be reasonably certain that the number of turns on it is going to work fine.

Crunching the numbers:

Inputting the above to the spreadsheet from the Homo Ludens page one can see that it does not actually care about the output current, but rather is tells you the

highest possible load current and volt-amp capacity based on the core size and flux density that you specify and the most important information that it gives is the number of turns for the primary: It is up to you to scale back the "worst case" numbers that it gives you to better suit your needs and make sure that everything will fit in the available space.

For example, given the information that we already have, the spreadsheet calculates that with the entered parameters one could expect to pull well over 26 amps at 11.5 volts - about 292 volt-amps using the wire targets along with what is calculated to be able to fit given the calculated wire sizes and the inputted fill factor. In reality, we will need closer to

(11.5 volt * 22 amps =) 253 volt-amps so we would be safe in downsizing our wire to about 83% of the calculated cross-sectional area. Assuming the worst case loading of the primary - which occurs at the

lowest primary voltage, 115 VAC, we can calculate that our maximum primary current will be

(253

volt-amps / 115 volts) = 2.2 amps.

- If we consult a wire table to see which size most closely matches our 0.4mm2/amp criteria (e.g. 0.4mm2/amp * 2.2 amps = 0.84mm2) we find:

- 17 AWG wire at 1.04mm2. This is (1.04mm2 /amp / 2.2 amps) = 0.472 mm2/amp.

- 18 AWG wire at 0.823mm2. This is (0.823mm2/amp / 2.2 amps) = 0.37 mm2/amp.

- 19 AWG wire at 0.653mm2. This is (0.653mm2/amp / 2.2 amps) = 0.30 mm2/amp.

As we can see, either 17 or 18 AWG would be fine for the primary, both sizes being quite close to our design goal: 17 AWG will run a bit cooler with lower loss while 18 AWG will take up a bit less space on the bobbin. 19 AWG does fit within the Edcor guidelines but is

much smaller than target - but would still probably be OK if one is willing to tolerate a bit of extra heat and voltage drop.

Based on the 1.4 Tesla flux values we can see that at 115 Volts and 60Hz we would need 223 turns on our primary to achieve the target of 11.5 volts and since the ratio of primary-secondary turns is exactly the same as our voltage ratio, we can calculate:

- 115 volts / 11.5 volts = 10:1 ratio

What this means is that for our 223 turns on the 11.5 volt primary, we would need

(223 / 10) = 22.3 turns. Since it is awkward to wind a fractional turn, let's round the secondary down to 22 turns - an even number that also makes it easy to locate the center tap point. By decreasing the number of turns slightly we must now recalculate the 115 volt primary winding using the same ratio as above:

- Doing this, we will need (10 * 22) = 220 turns. This reduction in turns from 223 increases the flux density on the core, but only by a few percent so we can ignore it.

Let us now calculate the number of turns for 120 and 125 volts:

- 120 volts / 11.5 volts = 10.435:1 ratio. 22 turns * 10.435 = 229 turns, rounded down.

- 125 volts / 11.5 volts = 10.870:1 ratio. 22 turns * 10.870 = 239 turns, rounded down.

Since we need

two filament windings, each capable of of 11 amps, we calculate the appropriate wire size for each:

- For 11 amps, we calculated a minimum wire cross-sectional area of (0.4 mm2/amp * 11 amps) = 4.4 mm2. Consulting the table, we find:

- 10 AWG wire at 5.26mm2. This is (5.26mm2/amp / 11 amps) = 0.48 mm2/amp

- 11 AWG wire at 4.17mm2. This is (4.17mm2/amp / 11 amps) = 0.38 mm2/amp

- 12 AWG wire at 3.31mm2. This is (3.31mm2/amp / 11 amps) = 0.30 mm2/amp

- 13 AWG wire at 2.62mm2. This is (2.62mm2/amp / 11 amps) = 0.23 mm2/amp

From all of the above we can see the 11 AWG wire is very close to our 0.4mm

2/amp target - and still above the recommendations of the two web sites listed above while 12 AWG appears to be suitable if one goes with the Edcor guidelines. It should also be noted that because these primary windings are on the "outside" layer

(the reason to be noted later) they can more readily dissipate heat via convection and conduction than a winding deep inside the bobbin.

Comment:

Instead of using 11 AWG, I could have used four parallel strands of 17 AWG as they would have a total of (1.04 * 4) = 4.16mm2 cross-sectional area - although handling multiple conductors at once can be quite awkward. One might do this if larger wire was not on-hand, but also to take advantage of the fact that 17 AWG is more flexible than 11 AWG. When paralleling conductors care must be taken to make sure that all are wound identically to prevent the differences in their intercepted magnetic fields which can cause "bucking", resulting in heating.

Will it fit?

As it turned out, I had suitably large quantities of 10, 11 and 17 AWG on hand so I decided to calculate the volume that would be taken up by the three sets of windings. Based on online drawings of the Edcor E150 nylon bobbin - and actual measurements with a set of calipers - I came up with the following:

- According to the drawing the interior width is 53.28mm but the actual, measured size was 52.7mm.

- The indicated window "height" (e.g. the available space on one of the four sides into which the windings must fit) is 16.935mm, but the actual, measured size was 16.5mm.

First, we calculate how many turns of 17 AWG will fit on a layer. The wire that I used

(polyimide coating, rated for operation to 200C) has a diameter

with insulation of 1.224mm which means that (52mm / 1.224mm/turn) = 43.05 turns may fit in a layer. Rounding down and accounting for a 1-2 turn of "fudge factor"

(e.g. wire laying with a slight amount of space between adjacent turns, a slight bit of wastage at the ends where the next layer starts) we can reasonably expect 41-42 turns per layer.

Knowing that we will need 239 turns for the 125 volt winding this comes out to

(239 turns / 42 turns/layer) = 5.7 layers so there should be no problem keeping it down to just 6 layers with a little bit of room to spare. Between layers I was laying down one layer of 0.05mm polyimide

(Kapton (tm)) tape which means that for each layer I was taking up

(1.224mm (wire) + 0.05mm (insulation)) = 1.274mm, and for 6 layers the total would be 7.644mm. Between the primary and secondary we need to put at least 0.5mm of additional insulation, bringing that up to a total of around 8.144mm of height out of the available 16mm.

Now taking the 11 AWG secondary we note that the diameter of the wire with insulation is 2.393mm which means that

(52mm / 2.393mm/turn) = 21.99 turns will fit on a single layer - and this number is a bit "soft" in that we

may be able to squeeze the full 22nd turn in if the nylon bobbin will flex just a little. Using the above numbers we can see that each layer will take

(2.393mm (wire) + 0.5mm (insulation)) = 2.893 mm - and since we have two identical windings that turns out to be 5.786mm, total.

All together, including a final 0.5mm thick layer of insulation, the height of the windings will be 13.93mm - about 84% of the available space and based on this I decided not to try the equations for 10 AWG. Out of curiosity I recalculated the above for 12 AWG we get

(52mm / 2.139mm/turn) = 24.31 turns fitting on a single layer with each layer+insulation being 13.442mm - about 81% so this would have been fine but because since I had 11 AWG on hand I decided to proceed with that size.

It was noted in the aforementioned Edcor Tek Note 43 that a reasonable design goal is around a 70% filling of the bobbin but that at 90% the numbers are re-crunched to see if smaller wire may be used and/or a larger core is required: Both of our numbers, above, come in below that 90% margin so we

should be pretty safe if we are neat and careful.

Calculating winding volume using "Fill factor":

"Fill factor" is the ratio between the volume occupied by the wire itself and the combined volume of the wires and insulation. Because a circle that is 1mm diameter occupies about 79% of the volume of a square that is 1mm on a side we lose over 20% off the bat in our packing efficiency - and this is made only worse by the fact that we need to add insulation between layers and also that we cannot pack the wires perfectly side-by-side. A bit less easy to calculate is the fact that at the ends of the bobbin where we transition between winding layers we tend to lose a portion of each turn at each end.

On the Turner Audio pages it was noted that a "Fill factor" of around 0.3 was common with older transformers with

(thick!) paper insulation between each winding and closer to 0.45 with modern insulation was practical while the Homo-Ludens site mentions that a fill factor of around 0.5 is practical if it is wound with care

(e.g. neat, side-by-side windings) and one uses thin, modern insulation.

How does our transformer "stack up" when using this method?

We know from above that the window size is

(52.705mm * 16.51mm) = 870mm

2, so let us calculate how much of the bobbin our wire is expected to take up:

- 17 AWG is 1.224mm diameter so its cross-sectional area is 1.177mm2, so (1.177mm2/turn * 249 turns) = 293mm2.

- 11 AWG is 2.393mm diameter so its cross-sectional area is 4.498mm2. (4.498mm2/turn * 22) turns (total for both windings) = 99mm2.

- The total of the copper alone is (293 + 99) = 392mm2, not including fill factor. Using this number with various fill factors we get:

- Fill factor of 0.3: 392 / 0.3 = 1307mm2. 150% of the available space - we must do better!

- Fill factor of 0.4: 392 / 0.4 = 980mm2. 113% of the available space - getting closer.

- Fill factor of 0.45: 392/0.45 = 871mm2. 100.1% - this is almost exactly how how much room we have.

- Fill factor of 0.5: 392/0.5 = 784 mm2. 90% - we should be fine if we can do this.

According to this method of calculation we will need to achieve a fill factor of about 0.45 in order to have the turns actually fit. Will the fact that the thin

(0.05mm) insulation between layers is thin

enough that overlaying windings will take up less "height" if they can

fall in the grooves between wires somewhat? Can this fill factor actually be achieved?

Let's find out.

|

Figure 2:

The prepared bobbin, at the start of the wind, covered with an initial layer

of polyimide tape.

Click on the image for a larger version. |

Winding the transformer:

While it might seem customary to wind the primary first, this is not always the best strategy. It is often the case that the

thinnest wire is wound first as the corners of the bobbin are their sharpest when the diameter is small, making it easy to handle and allowing slightly better packing efficiency and, thus, a better "fill factor." In this case, because the primary used thinner wire

(17 AWG) than the secondary

(11 AWG), I did wind the primary first.

In preparation for the start of winding I placed a layer of 0.05mm polyimide tape onto the nylon bobbin as a foundation and to give the wire a bit of a surface to "bite" into - and to provide just a little more protection even though it is unlikely that the transformer could ever survive the sorts of conditions that would melt or arc over the bobbin in the first place!

|

Figure 3:

The three primary voltage taps.

As may be seen, the lower voltage taps (115, 120 volts) consists of a loop

of wire that is brought out of the winding. The locations of these taps

is staggered somewhat to space apart where they emerge from the side

of the bobbin: The slight, fractional-turn deviation from the calculated tap

location causes an insignificant voltage change on a winding with this

many turns. With the taps emerging at a right angle, away from the

"corners" of the bobbin they will add wire height only to the portion

that faces the end bells of the transformers, not on the "sides" between

the winding and the steel laminations which would be on the top

and bottom of this picture. This method of bring out the taps

also prevents the taps from significantly reducing the number of turns

that will fit on the layer which can keep the number of layers down

to that calculated.

Click on the image for a larger version. |

Because 17 AWG wire is actually quite large I "drilled" a hole through the nylon with the conical tip of a hot soldering iron

(easier and safer to do than with a drill - particularly when there are already windings present on the bobbin that could be damaged by the bit) and brought the wire straight out the side of the bobbin. Winding excess length around the screws of the bobbin holder that were placed there for the purpose of keeping this wire out of the way, I proceeded to place the first layer.

Winding very carefully I laid the turns side-by-side and pushed them closer together to reduce the space after every few turns. At the end of the first layer I temporarily taped the wire to the side of the bobbin to keep it from unraveling and put an even layer of 0.05mm polyimide tape over the first layer to both insulate and secure the windings before starting the next layer.

Because the first layer was wound very neatly, the second and subsequent layers usually fell into the grooves between the windings of the previous layer with this thin insulating tape which can make it easier to keep these layers nice and neat. At the ends of the winding there can be a bit of "mechanical confusion" as there is inevitably a sort of "half turn" of spacing between the wire and bobbin that cannot be effectively filled. As one continues to add layers, this gap on the ends tends to gradually become deeper and care must be taken to make sure that as the wire

(inevitably) falls into this gap that it falls atop insulation rather than the underlying wire - particularly from deeper layers - as to minimize the possibility of the wire being chafed and shorted with vibration and thermal cycling.

|

Figure 4:

A side view of from where the primary taps emerge. It is important

that the taps be labeled at the time of winding to avoid later

confusion and the possible need to reverse engineer what was done! Small

pieces of Nomex paper insulation are visible, used to mechanically

separate the overlaying conductors.

Click on the image for a larger version. |

At turns 220 and 229 the winding was paused to make the 115 and 120 volt taps. This was done by making a loop of wire approximately in the middle of the face of the winding, bringing the two wires of the loop together so that they carefully lay side-by-side and bringing it out the side of the bobbin through a hole that was labeled with a permanent marker. Underneath this loop was placed both some polymide tape and some Nomex

(tm) paper insulation to prevent the pressure of the wires of these taps from impinging directly on the insulation of the turns below it and shorting some turns. At the very end of the winding the tail end of the wire was brought directly out through a labeled hole.

Over the top of the taps was placed an additional layer of polyimide tape and the entire primary was then covered with of a combination of Nomex paper and polyimide tape to provide a durable insulation between it and the secondary. Up along the sides of the bobbin a few millimeters of extra insulating tape was added to increase the "creep" distance - an important safety factor when high voltages are concerned.

Once this was done it was time for the secondary windings. Because 11 AWG is quite large, it takes a bit of brute force to handle. Using a pair of strong needle-nose pliers a fairly sharp right-angle bend was made in the wire so that it could pass through the slightly oversized hole that I had melted into the side of the bobbin without taking up too much extra space and the winding proceeded with the wire being bent carefully around each corner of the bobbin.

|

Figure 5:

The completed bobbin, overtaped with taps coming out several sides.

The thin center-tap winding of the outer filament winding (yellow-orange

wire) is easily visible with the purple center tap of the inner filament winding

being seen in the background. Since the center tap carries only the tubes'

cathode currents, the center taps need only carry a few hundred milliamps

at most.

Click on the image for a larger version. |

As it turns out, only about 21 and a fraction turns of the required 22 turns would actually fit across the bobbin so a new layer was started that had just one turn - but this extra turn was lined up with the partial final layer of the primary so its total height was less than it would otherwise have been. Carefully making a fairly sharp bend in the wire and passing it through a labeled hole in the bobbin, I then located - by counting from each end - the exact location of the 11th turn - the center-tap. There I carefully scraped the insulation off the top of the wire and, with a

very hot soldering iron it was tinned and a short piece of PTFE (Teflon (tm)) covered wire was was attached and brought out through a labeled hole in the side of the bobbin.

While this method of connecting the center-tap is a bit kludgy, the use of magnet wire with a high-temperature polyimide insulation and the underlying polyimide tape between layers minimizes the possibility that the wire itself will be damaged in the process of soldering - and careful visual inspection and tugging on the added tap wire indicated that the connection was quite secure and that the wire itself and insulation in neighboring turns were still intact.

The use of a very hot iron may seem counter-intuitive, but having a lot of heat and thermal mass means that one can thoroughly heat the wire rather quickly to make a proper, alloyed solder connection. Because the center tap is low-current, needing to carry only a few hundred milliamps of cathode current from the tube, the tap wire is quite small - about 24 AWG. If I do this technique again I will insert a piece of tape as a "cradle" at the tap point during winding to add extra insulation around the location of the tap and the adjacent turns.

Finally, this "tack" method of attaching the low-current center tap results in a connection that is mechanically weak and easily broken if it is yanked. Additional strength is given to this connection by the under and over taping done to insulate and protect this wire, but it is recommended that one

not use these center-tap wires to pick up the transformer!

|

Figure 6:

A side view of the completed bobbin.

Before the transformer's end bells are installed, wires will be attached to

the primary winding's connections and the heavy filament wires will be protected

with an additional layer of insulation where they are brought out.

Click on the image for a larger version. |

The first primary completed, it was covered with a layer of 0.05mm polyimide tape, a layer of 0.05mm Nomex paper and another two layers of 0.05mm polyimide tape.

To avoid cluttering the bobbin with too many holes that were too close to each other, the second primary was started nearly 1/4 turn away from the first primary

(at nearly the next corner) and since the first had taken a bit more than one layer, I had to "offset" the start of the winding slightly, crossing over the top single-turn top winding of the first primary. Understandably, this was done with care, bending a slight loop in the wire to go up and over with plenty of insulating tape and a piece of Nomex paper slid underneath to protect the adjacent wires.

The winding proceeded from there, but since it could not start at the end of the bobbin there were now several turns at the end in an "extra" layer that required yet another careful "crossing of the wires" with plenty of insulation. Upon securing the winding the exact middle of the secondary was located - a task made slightly more difficult by some of the turns being overlaid on a new layer and the center tap was carefully made in the same manner as before.

The winding being done, the second secondary was covered with several layers of polyimide tape and, using a clamp and two pieces of wood, the windings on the two sides of the bobbin that were not facing outwards were squeezed together, slightly reducing the height and increasing the spacing where it passed through the core.

|

Figure 7:

The "primary side" of the transformer with the solder

joints having been doubly-insulated with heat-

shrinkable tubing.

Click on the image for a larger version. |

The results:

As it turned out, the windings - including the unintended partial layer on the secondaries - completely filled up the bobbin, but there was easily a millimeter or two clearance between the windings and the laminations.

In testing the transformer unloaded using a variable transformer I ended up with the following results:

- 115 volt primary tap at 115.0 volts: 11.49 and 11.48 VAC on windings 1 and 2, respectively

- 120 volt primary tap at 120.0 volts: 11.49 and 11.49 VAC

- 125 volt primary tap at 125.0 volts: 11.52 and 11.51 VAC

- Accuracy of center-tap voltage: Better than 50 millivolts on each winding.

- The magnetization current (no load) was approximately 300 mA on each tap at its rated voltage, decreasing somewhat with the higher-voltage taps. It should be noted that the magnetization current is about 90 degrees out of phase with the reflected load current so it won't count too very much against us when the transformer is actually under load.

|

Figure 8:

The "secondary" side of the transformer. The heavy

(11 AWG) wires are first insulated with PTFE

insulation and where they emerge from the metal

bell are covered with colored heat-shrinkable tubing

to identify the windings. |

One of the reasons for the primary taps is to allow "fine tuning" of the filament voltage: Putting taps on the relatively low-current primary is much easier than providing several

pairs of equal-spaced taps on the center-tapped, high-current secondary!

As it turns out the actual heater voltage of the tubes that will be used is 10.5 volts, but it is common practice to purposely add a bit of series resistance to reduce the "cold filament" inrush current when the power is first applied - something that will likely involve a drop of a few hundred millivolts through additional resistance: Anyway, it is much easier to drop a small bit of voltage than add it!

What if we

did need more filament voltage than our 11 volt (loaded) target? The worst-case scenario would be to run the 115 volt tap at 125 volts

(yielding 12.5 unloaded volts on the secondaries) which would increase the magnetic flux of the core to an estimated 1.48 Tesla - still within the "safe" range for the M-6 core material!

Lessons learned:

The entire reason for doing this task is to learn something, so here are a few comments:

- The "tack" method of attaching the center tap wire to the secondaries seems to work OK, but I can see that it was not done very carefully, it could easily go wrong for a number of reasons:

- Damaging the insulation of adjacent turns and causing immediate or future problems with shorting. The use of high-temperature polyimide wire allowed this to be done safely, but in the future I would lay the tap point in a "cradle" of polyimide tape to provide additional protection to the adjacent turns.

- A faulty solder joint due to inadequate breaking of the insulation on the top surface of the wire and/or insufficient heat to make the joint.

- This method of attaching a comparatively thin conductor is only appropriate where the current through the center tap will be quite small. In this case, only the cathode current of the tubes - a few hundred milliamps at most - is all that need be conveyed.

- I did not end up with much additional room on the bobbin when the winding and final insulation layers were completed. Were I to design and build this transformer again and I were willing to buy whatever sized wire I needed I would probably have used 18 AWG for the primary.

- 12 AWG would have probably been just fine for the secondaries, particularly with the use of modern, high temperature wire and insulation and the fact that the two secondaries are on the "outside" of the bobbin. The use of 12 AWG would have also easily allowed each layer of 22 turns to be would with a little bit of room to spare.

- Had I used 18 and 12 AWG wire for the primary and secondaries, respectively, there would have easily been enough room to add yet another secondary winding such as a 6.3 volt winding for tube filaments or even yet another low-current winding for bias, control logic, or whatever.

Overall, I'm pleased with the results.

Final comments:

The transformer has yet to be encapsulated in insulating varnish and shims have not been inserted between the core laminations and the bobbin, so it hums a lot more now than it will when it is complete. It will not be until after the initial testing of the

(yet to be constructed) amplifier that this will be done as it will still be possible to make slight modifications to the transformer

(e.g. change the number of turns, add extra, low-current windings, etc.) in its present state.

In static

(no load) testing the transformer was operated with 130 volts applied to the 115 volt tap resulting in an estimated 1.54 Tesla core flux, a

28C (50F) temperature rise was observed. When 115 volts was applied to the same tap - a situation more representative of

core losses

(not including the resistive losses in the winding) that might be observed in actual use the temperature rise was just 19C

(30F).

* * *

How long did it take to wind this thing? With all of the materials and components lined up it took less than two hours to wind this transformer - being very careful - and about another hour to stack the cores and do initial testing using a variable transformer supply.

The next installment will describe the design and construction of the high voltage plate transformer.

[End]

This page stolen from "ka7oei.blogspot.com".